News

Conversion of Traditional Olive Groves

We understand traditional olive groves as those constituted by centuries-old olive trees, spaced widely apart in expansive exploitation patterns, ranging from 9x9 to 14x14. In numerous seminars and congresses related to olive groves and olive oil, the conclusion of many experts in this sector is always the same: "Traditional olive groves must be transformed." This conclusion is reached by acknowledging that the future of the sector lies in maximum mechanization. We must not forget that the serious problem with traditional olive groves is the low or nonexistent profitability in a market with low olive oil prices.

In this way, the reconversion must be approached as a goal

to make the olive grove mechanizable, increase production, and maximize profit

through cost reduction. To achieve this, we begin by acknowledging a series of

premises:

- We

know that the best reconversion for a traditional olive grove with wide

spacing is to remove them and replace it with an intensive olive grove

that, with proper care, will provide us with the same or even more

production than the traditional one in 7-8 years, with annual increases

until reaching its maximum leaf volume.

- We

know that not all farmers can carry out this type of transformation due to

various reasons, especially economic ones due to the total loss of

production for several years.

- We

know that planting new single-stem olive trees among existing multi-stem

olive trees faces greater challenges in development due to various

reasons, especially due to competition for water and light.

With this in mind, this article proposes a reconversion of

the traditional olive grove for planting frames of 12x12 m with 69 trees/ha, or

14x14 m with 51 trees/ha. We are referring to all olive trees with 3-4 stems or

trunks, with the idea of transforming them into frames of 12x6 with 139

trees/ha and 7x7 with 204 trees/ha, respectively, with single-stem olive trees,

and enabling mechanized harvesting using an inverted umbrella shaker. While we

recognize that this system is not ideal, it minimizes the loss of production

during the reconversion process, significantly reduces production costs, and

increases production once the reconversion process is completed. In this

regard, we propose a progressive transformation over a period of 8-10 years.

The steps to follow are as follows:

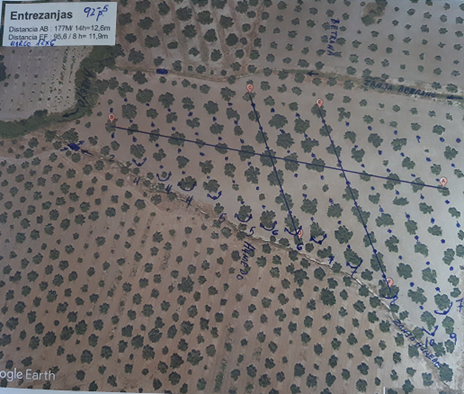

- Determine the spacing of the olive grove to be converted. This can be known by measuring with a measuring tape (more accurate) or using an aerial photo from the Google Earth application (which can be done on the same plot screen). In photo #1, two rows of crossed olive trees have been measured, one measuring 177 m and divided by the number of gaps, 14, resulting in a measurement of 12.6 m. The other crossed row measures 95.6 m with 8 gaps, resulting in 11.9 m. The spacing of the plot in the photo is 12x12. The advantage of the aerial photo is that it allows the spacing to be calculated and the density increase to be replanned on the photo without having to visit the plot.

Photo 1: Calculation of the spacing of a plot using the

aerial photo from the Google Earth application. (PHOTO: Valencian Institute of

Agricultural Research).

- In

the replanting of new olive trees, it is necessary to define:

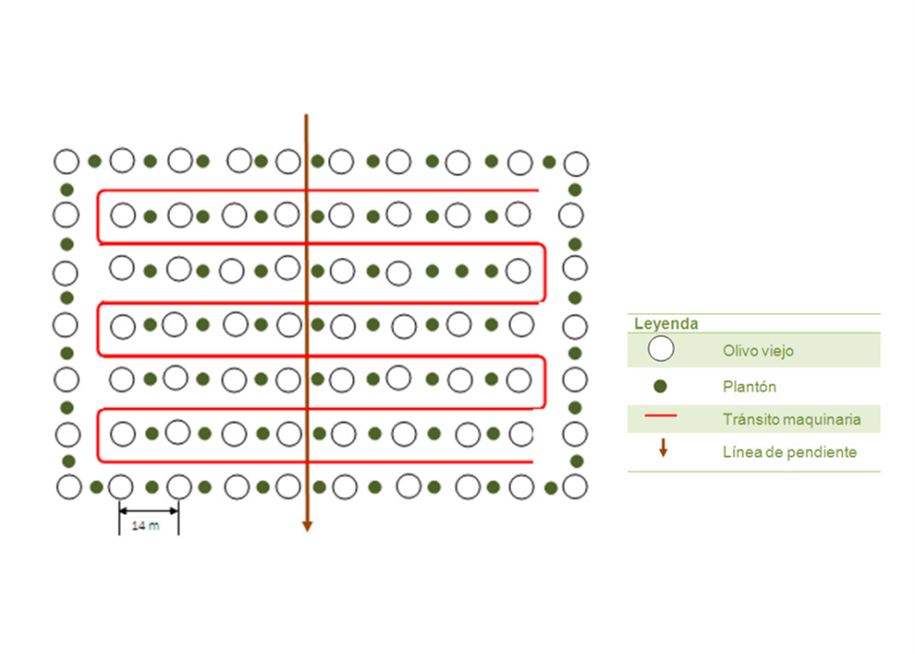

· The main working aisle, which should be perpendicular to

the slope of the plot. In the case of the conversion from 12x12 to 12x6, the

main aisle will be 12 meters.

· The movement of machinery, especially the turns at the end

of the row of olive trees, to minimize invasions and disturbances to the

neighboring property.

F-2 Theoretical Design of a Conversion. (PHOTO: Valencian

Institute of Agricultural Research).

- Determine

the centers of the rows by measuring from the center of the trees and mark

a reference at the start and end of each row, which will serve as a guide

for subsoiling the center of the row. Once the subsoiling is done, proceed

to use a rake to smooth the terrain and break up clumps.

- Mark

the positions of the olive trees to be planted and dig the planting holes.

- Use

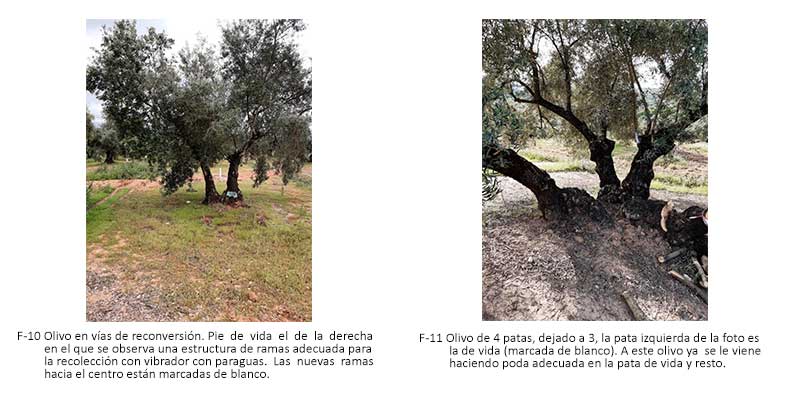

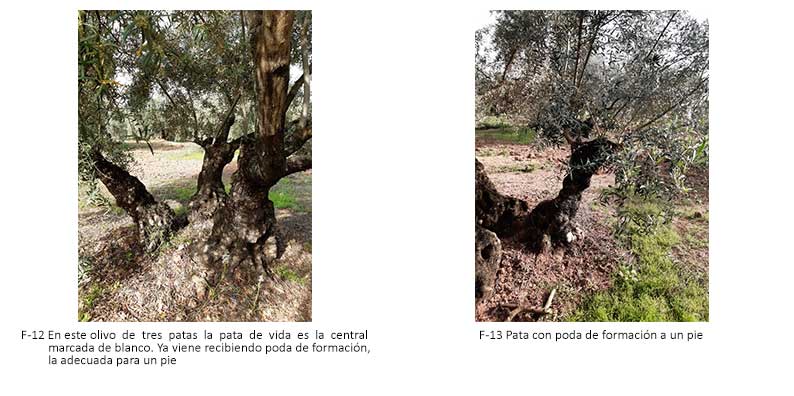

paint to mark the selected live trunk or base of life that will remain on

each tree from the traditional olive grove. This choice is made based on

its potential future mechanization. Factors considered include height,

slimness, diameter, and trunk health. Within this selection, there may be

olive trees that won't undergo conversion and their only solution will be

uprooting.

- Initiate

pruning or cutting with the goal of promoting the development of the live

trunk, encouraging the growth of shoots or suckers towards the empty space

in the central zone of the olive tree. Annual cleaning of the head of the

trunk or live trunk is recommended, selecting the best-oriented shoots and

removing any obstacles that hinder their proper growth from the vegetation

of other trunks. Ideally, this pruning or cutting system should start a

few years before trunk cuts and planting. The aim of pruning and cutting

is for the live trunk to have 4-5 branches around the head of the trunk,

with angles of approximately 60 degrees to the horizontal. This is

achieved through successive prunings. In the traditional pruning of an

olive tree with multiple trunks, preference is given to olive trees with

compact growth that facilitate harvesting, with branches that are not very

vertical, and sometimes nearly horizontal. Occasionally, some branches may

reach the center of the rows, and low-hanging branch remnants may be left very

close to the ground. With mechanization using an inverted umbrella

vibrator, pruning changes. Slim branches (60 degrees to the horizontal

axis) are sought, as they vibrate better, visible trunks to aid the

attachment of the vibrating clamp, and low-hanging lateral branches at a

certain height so they do not touch the inverted umbrella, as any branch

that touches the umbrella's folds does not vibrate. For harvesting with an

inverted umbrella vibrator, olive trees need taller canopy heights, with a

maximum canopy diameter limited to the umbrella diameter, and lower

branches must be maintained at a greater height from the ground. For

harvesting with an inverted umbrella vibrator, the pruning systems for

formation, maintenance, and renewal differ from the conventional

multi-trunk olive grove. In formation pruning, the cut is made above the

sap vein to induce shoot regrowth in appropriate areas and topping to

reduce vigor.

The photo shows the live trunk marked in red (left), with a deformative pruning already initiated on the live trunk. We can also see that the other existing trunk has undergone conventional pruning, aiming not to hinder the vegetative growth of the main trunk. In this olive tree, the process of removing trunks or bases has already begun.

F-3: Note the slender (60º) insertion of the main branches suitable for proper vibration transmission

(PHOTO: Valencian Institute of Agricultural Research)

F-4: Tree with some branches inserted at too wide an angle that do not transmit vibration well

F-5: Branch resting on the canvas that prevents good vibration transmission

Details of the conversion of an olive grove 12x12

During this conversion, many of the live trunks are not

entirely straight. It's common for them to be somewhat tilted. In others, the

canopy volume is off-center in relation to the trunk axis. All these inevitable

imperfections in this type of conversion influence the quality of shaking and

gradually correct themselves naturally with proper pruning. It's crucial that

pruning practices are controlled and guided by the person conducting the

conversion, who must have a clear understanding of what they want to achieve

and must do.